Crew Transfer Vessels

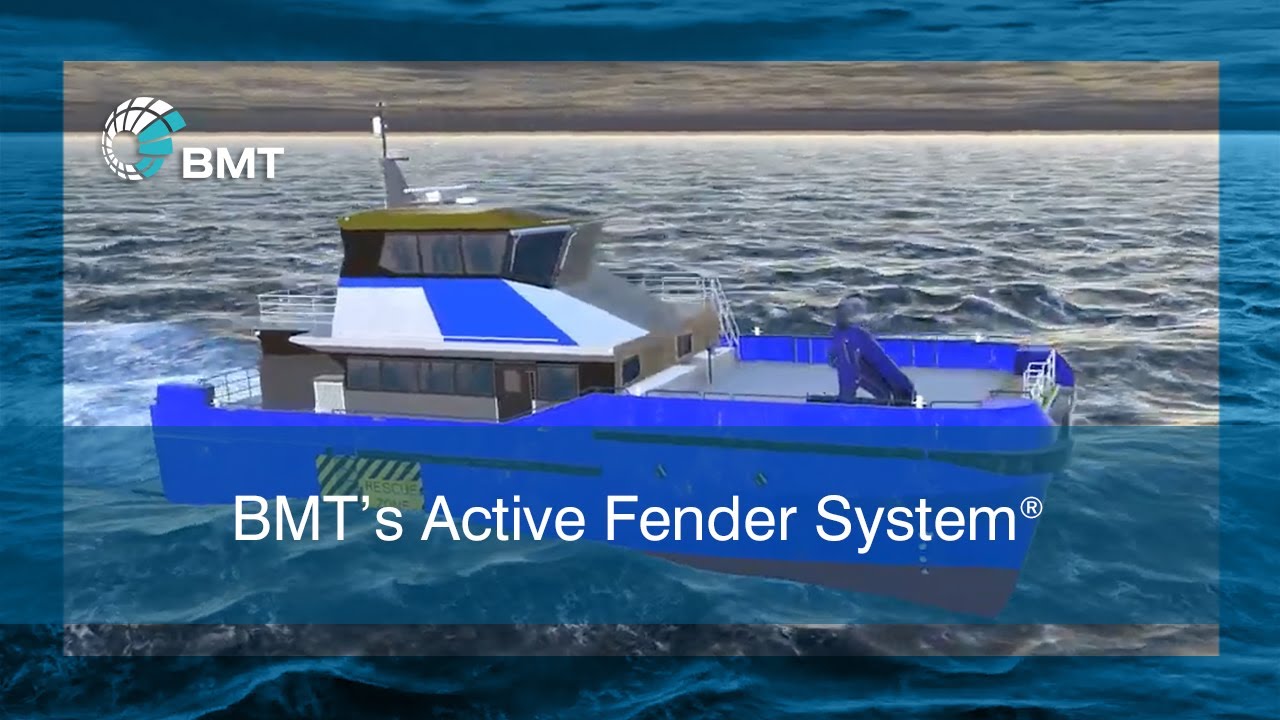

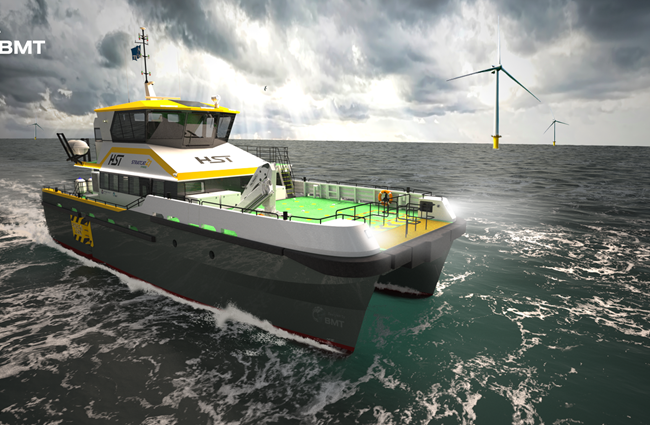

CTVs are explicitly designed to transport service teams to offshore wind farms. They have become more prominent, more robust to service wind farms further offshore and are usually fitted with bow fendering explicitly suited to wind turbines.

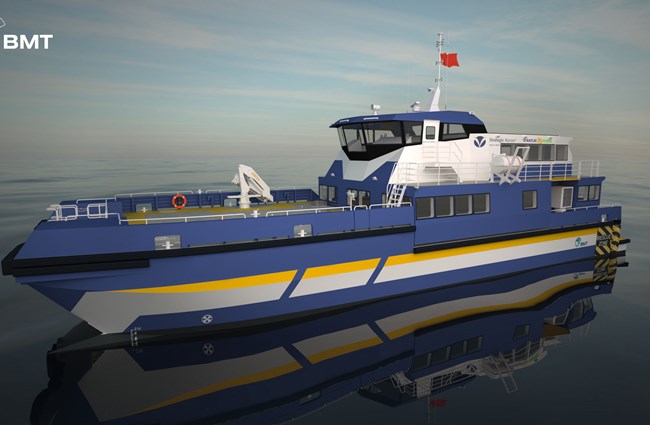

All our CTVs are designed to be efficient and work effectively in various offshore environments. Advanced hull forms such as our XSS (eXtreme Semi-Swath) provide that capacity along with improved seakeeping and operability. Our larger offshore fast crew boats also deliver class-leading fuel efficiency for the oil and gas market.

We’re continually increasing the range of available sizes of our proven CTV designs from 18 metres to over 30 metres. New, longer vessels meet the industry’s growing demand for capacity and prolonged offshore operations.

Offshore Support Vessels

OSVs can be divided into several types according to operations they perform: seismic survey ships, platform supply vessels (PSV), anchor handling tugs, anchor handling tug and supply vessels (AHTS), offshore construction vessels (OCV), ROV support vessels, dive support vessels, stand-by vessels, inspection, maintenance and repair vessels (IMR) and variety of combinations of these.

Our platform supply vessels are designed for servicing offshore drilling rigs and production platforms with the necessary equipment, stores and drilling consumables.

OSVs may have additional cabins, mess room facilities, and offices to accommodate the support crews comfortably.